You are reading the first ever "review" of the

Akafugu Nixie Modular Clock, a product yet to be released at the time of writing. Per, of Akafugu, generously offered to sell me the PCBs for this Nixie clock; the parts were sourced by myself.

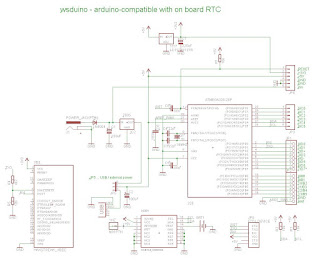

The Nixie Modular Clock shares a big chunk of the schematic with its older sibling, the

Akafugu Nixie Clock. The goal of this latest design is, I assume from the name, the "modularity". Similar to the

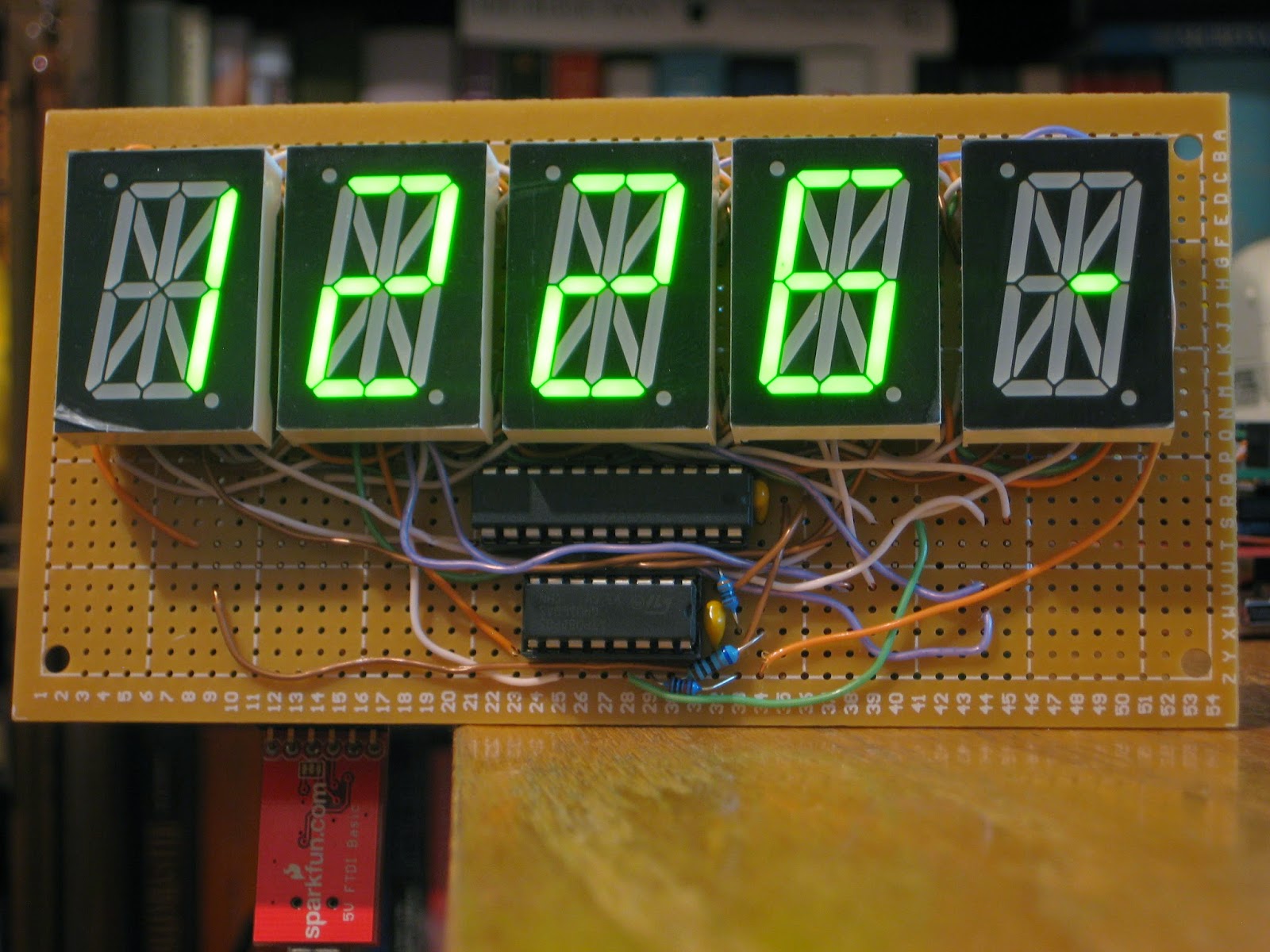

VFD Modular Clock, "shields" for various types and numbers of Nixie tubes will probably be developed soon.

The hardware

This Nixie Modular Clock is an Arduino-based, open source project, designed around ATmega328 running on internal oscillator at 8MHz. Like the Akafugu Nixie mk3, the high voltage source (180-200V) uses the

MC34063 DC-DC converter, and the driver for Nixies is

HV5812. There are 3 buttons: 2 in the back, for setting up the time and alarm time, and another long-stem, protruding through the top board, for enabling/disabling the alarm. An orange LED in the front indicates if the alarm is active or not.

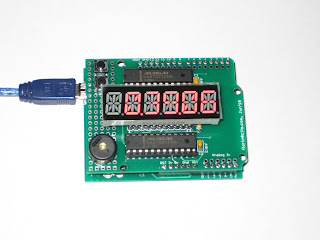

The PCB for the commercial version will be red, I was told (as shown below :).

Assembly

Building the clock is straightforward (as long as all parts are in hand, which will be the case when the kit becomes available). The

assembly instructions are easy to follow and very clear, with lots of details and helpful photos. Some of the parts I picked (electrolytic capacitors, inductor) were a little too high, so I had an issue with the clearance between the 2 boards. I was able to "correct" that (meaning increase the distance between boards) by using long-legged headers lifted on male-headers plastic insulators (see the photo below).

I did not install the lamp between the hours and minutes. I was surprised to see that the unit-hours tube (second from left) blinks its decimal point!

The clock has also support for "background" LEDs (blue recommended), but I did not solder those either.

The software..

..is also open source and

available here. A nice feature that every programmer will love is that it covers both Nixie Clock and Nixie Modular Clock (plus variants of the latter, like 6-tube clock) by using macro definitions. Not to mention that the code compiles and works without a glitch. It also has support for GPS.

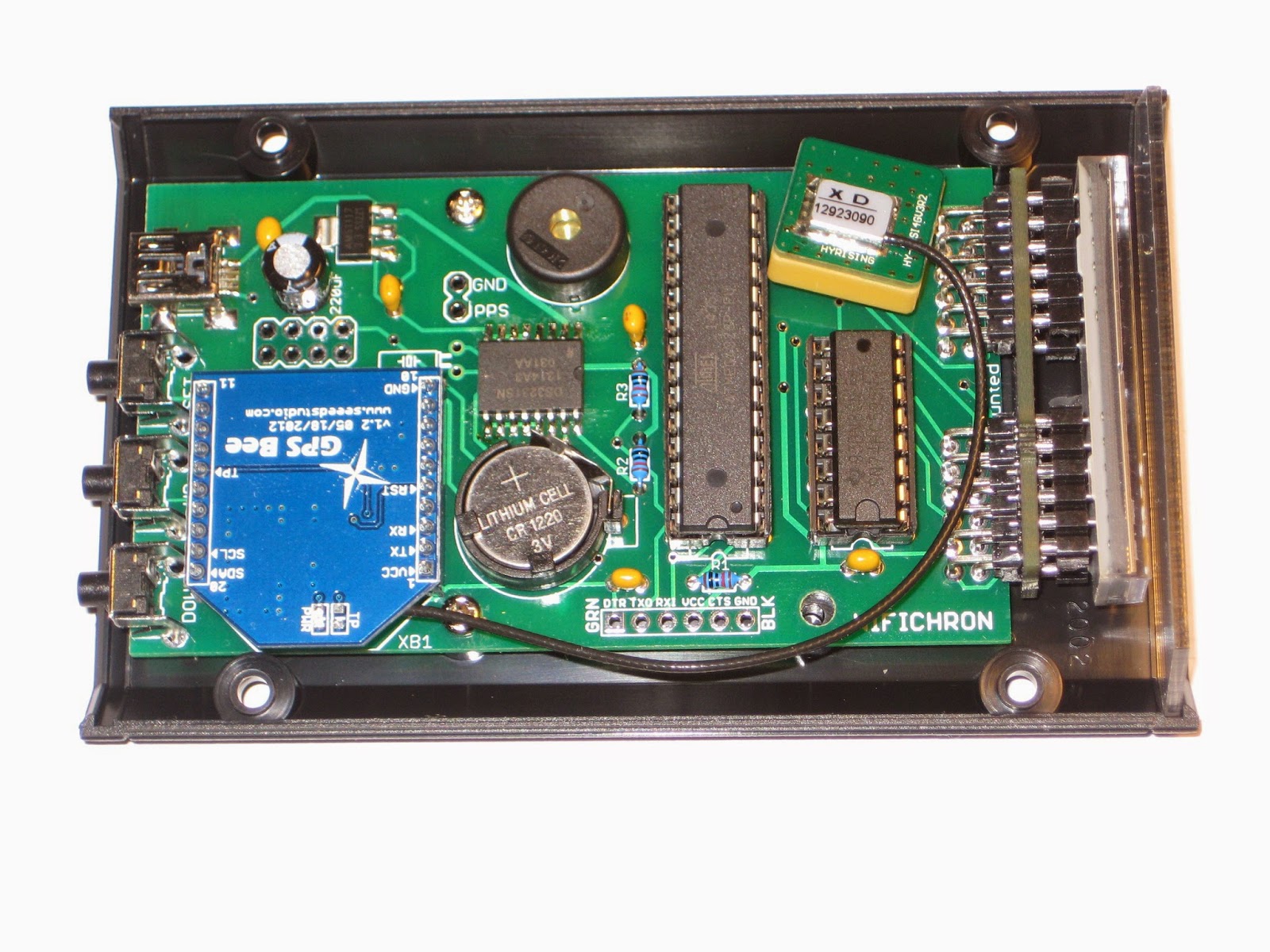

Enclosure

Although I like the elaborate enclosure that Akafugu designed, I tried my own, by using simple plates to cover the exposed soldered pins, on both top and bottom. To me, the open sides are ok as long as small children don't stick their fingers (or grownups screwdrivers) in there :)

My suggestion is to make the top plastic plate of the enclosure (shown in

akafugu's photo of the clock) transparent, rather than opaque black, which hides the elaborate design/silkscreen of the tube PCB.

Conclusion

I think that the Modular Nixie Clock will be another success. Its aesthetics, compact size and feature-rich software set a new standard in the world of Nixie clocks. Remember, most of the Nixie clocks one can buy on etsy, ebay or other sites, are non hack-able hardware or software. If you want one to tinker with, then Akafugu Modular Clock is for you.